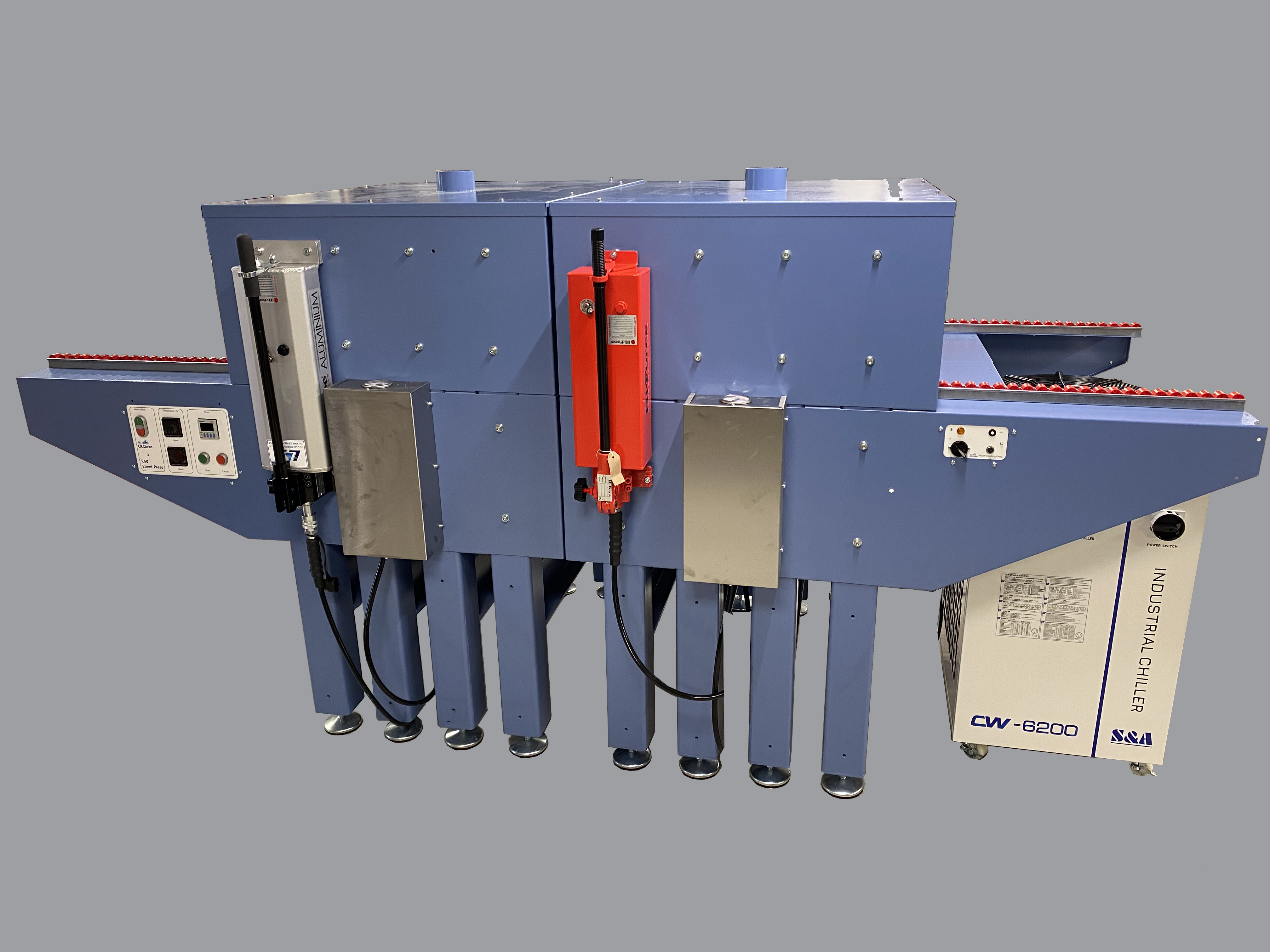

The R60 Sheet Press converts granulated thermoplastic material into a usable form using heat and high pressure. As standard, the formed article is a flat plastic sheet, which can typically be used for vacuum forming, laser cutting, line bending etc. There are also tools available for making shaped parts, for example Frisbees, on the machine.

A removable material cassette is placed onto the loading roller track and filled with granules of the material to be pressed. The cassette is manually pushed into the pressing position and clamped firmly between two temperature controlled aluminium hotplates. The heat and pressure causes the material granules to soften and fuse.

At the end of the pressing cycle, the material cassette is rolled out and allowed to cool. The formed panel of material can then be removed and used. The R60 is a freestanding unit.

It is recommended that a Fume Extraction system is used with the R60, please contact us for more details on this.