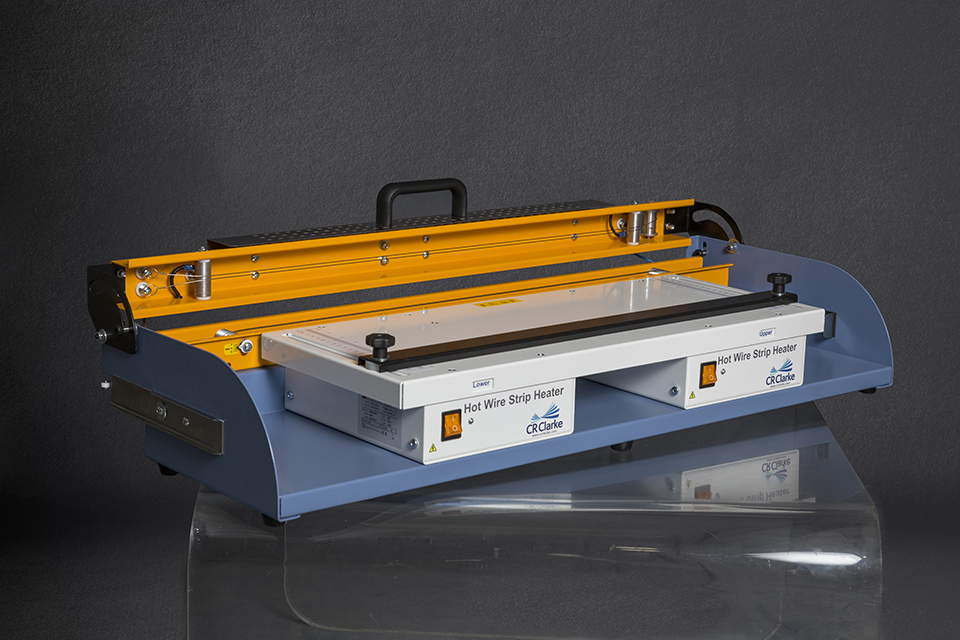

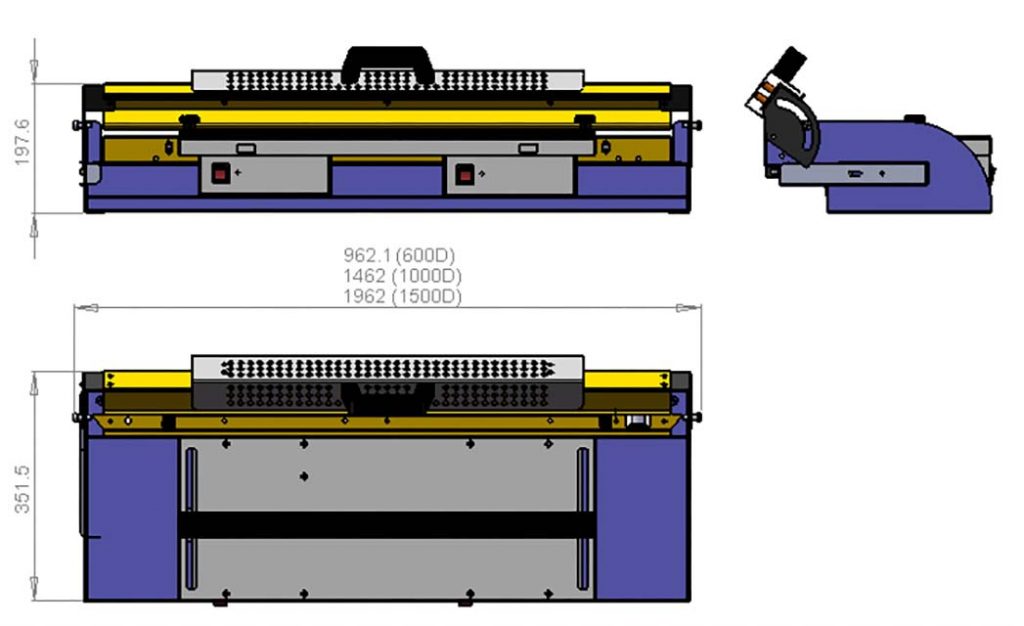

The D range of Hot Wire Strip Heaters is available in three working lengths – 600, 1000 and 1500mm. Each machine is fitted with multiple hot wires for performance and versatility.

These units have two wires mounted in a channel at the rear of the work table, with a further two mounted in the hinged upper channel. All wires are adjustable for spacing and air gap, allowing materials from 0.5 to 10mm to be processed quickly and efficiently. A calibrated workstop allows the user to accurately set the bend position, while the hinged upper beam also holds the material in position during the heating cycle. Safety switches de-energise all heating wires when the upper beam is opened, minimizing exposure to heated surfaces.

The machines are bench mounted and easily portable. A range of Folding Jigs is also available to support the material at the correct angle while cooling.

For educational use, the heating wires switch off whenever the upper beam is raised. This, coupled with the fast warm-up and cool-down of the heating wires, ensures maximum safety in operation. For industrial use, a Bypass switch can be activated, leaving the wires switched on at all times for maximum productivity.